"When I saw the leaves on the trees curl and turn black and birds fall dead out of the sky, I knew that this was Death, come among us as foretold. My regret is that I survived."

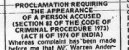

On December 3rd, 1984, thousands of people in Bhopal, India, were

gassed to death after a catastrophic chemical leak at a Union Carbide

pesticide plant. More than 150,000 people (1)

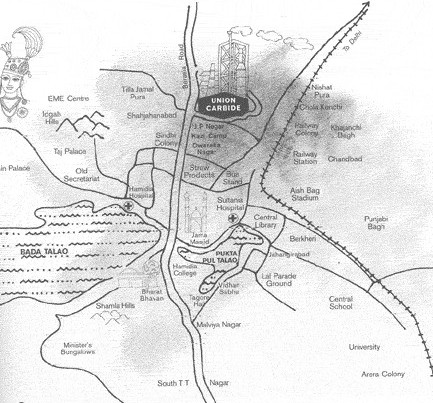

were left severely disabled - of More than 27 tons (3) of methyl isocyanate and other deadly gases turned Bhopal into a gas chamber. None of the six safety systems at the plant were functional, (4) and Union Carbide’s own documents prove the company designed the plant with “unproven” and “untested” technology, and cut corners on safety and maintenance in order to save money. Today, twenty years after the Bhopal disaster, at least 50,000 people (5) are too sick to work for a living, and a recent study in the Journal of the American Medical Association confirmed that the children of gas-affected parents are themselves afflicted by Carbide’s poison. Carbide is still killing in Bhopal. The chemicals that Carbide abandoned in and around their Bhopal factory have contaminated the drinking water of 20,000 people (6). Testing published in a 2002 report revealed poisons such as 1,3,5 trichlorobenzene, dichloromethane, chloroform, lead and mercury in the breast milk of nursing women living near the factory. Although Dow Chemical acquired Carbide’s liabilities when it purchased the company in 2001 (7), it still refuses to address its liabilities in Bhopal - or even admit that they exist. Till date, Dow-Carbide has refused to: 1) Clean up the site, which continues to contaminate

those near it, or to provide just compensation for those who have

been injured or made ill by this poison; Death came out of a clear sky. Midnight, a cold wind blowing, the

stars brilliant as they are in central India, even through the thin

pall of cooking-fire smoke that hung above the city. Here and there,

braziers were burning to warm those who were obliged to be out late.

From the factory which so many had learned to fear, a thin plume

of white vapor began streaming from a high structure. Caught by

the wind, it became a haze and blew Remembers Aziza Sultan, a survivor: "At about 12.30 am I woke to the sound of my baby coughing badly. In the half light I saw that the room was filled with a white cloud. I heard a lot of people shouting. They were shouting 'run, run'. Then I started coughing with each breath seeming as if I was breathing in fire. My eyes were burning."

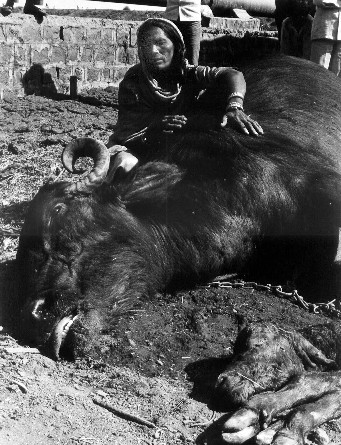

Another survivor, Champa Devi Shukla, remembers that "It felt like somebody had filled our bodies up with red chillies, our eyes tears coming out, noses were watering, we had froth in our mouths. The coughing was so bad that people were writhing in pain. Some people just got up and ran in whatever they were wearing or even if they were wearing nothing at all. Somebody was running this way and somebody was running that way, some people were just running in their underclothes. People were only concerned as to how they would save their lives so they just ran. "Those who fell were not picked up by anybody, they just kept falling, and were trampled on by other people. People climbed and scrambled over each other to save their lives – even cows were running and trying to save their lives and crushing people as they ran." In those apocalyptic moments no one knew what was happening. People simply started dying in the most hideous ways. Some vomited uncontrollably, went into convulsions and fell dead. Others choked to death, drowning in their own body fluids. Many were crushed in the stampedes through narrow gullies where street lamps burned a dim brown through clouds of gas. "The force of the human torrent wrenched children's hands from their parents' grasp. Families were whirled apart," reported the Bhopal Medical Appeal in 1994. "The poison cloud was so dense and searing that people were reduced to near blindness. As they gasped for breath its effects grew ever more suffocating. The gases burned the tissues of their eyes and lungs and attacked their nervous systems. People lost control of their bodies. Urine and feces ran down their legs. Women lost their unborn children as they ran, their wombs spontaneously opening in bloody abortion." When dawn broke over the city, thousands of bodies lay in heaps in the streets. Even far from the factory, near the lake, at Rani Hira Pati ka Mahal the ground was so thick with dead that you could not avoid treading on them. The army dumped hundreds of bodies in the surrounding forests and the Betwa river was so choked with corpses that they formed log-jams against the arches of bridges. Families and entire communities were wiped out, leaving no one to identify them. According to Rashida Bi, who survived the gas but lost five family members to cancers, those who escaped with their lives “are the unlucky ones; the lucky ones are those who died on THAT NIGHT.” How many thousands died, no one knows. Carbide says 3,800. Municipal workers who picked up bodies with their own hands, loading them onto trucks for burial in mass graves or to be burned on mass pyres, reckon they shifted at least 15,000 bodies. Survivors, basing their estimates on the number of shrouds sold in the city, conservatively claim about 8,000 died in the first week. (8) The official death toll to date (local government figures) stands at more than 20,000 and even now, twenty years later, at least one person per day dies in Bhopal from the injuries they sustained on THAT NIGHT. (9)

Bhopal is not only a disaster, but a corporate crime. It began as a classic instance of corporate double-standards: Union Carbide was obliged to install state-of-the-art technology in Bhopal, but instead used inferior and unproven technology and employed lax operating procedures and maintenance and safety standards compared to those used in its US 'sister-plant'. The motive was not simply profit, but also control: the company saved $8 million, and through this deliberate under-investment managed to retain a majority share of its Indian subsidiary. (11) It should have come as no surprise to Carbide’s management when its factory began to pose a chronic threat to its own workers and to the people living nearby. On December 25, 1981, a leak of phosgene killed one worker, Ashraf Khan, at the plant and severely injured two others. On January 9, 1982, twenty five workers were hospitalized as a result of another leak at the plant. During the "safety week" proposed by management to address worker grievances about the Bhopal facility, repeated incidents of such toxic leakage took place and workers took the opportunity to complain directly to the American management officials present. In the wake of these incidents, workers at the plant demanded hazardous duty pay scales commensurate with the fact that they were required to handle hazardous substances. These requests were denied. Yet another leak on October 5, 1982 affected hundreds of nearby residents requiring hospitalization of large numbers of people residing in the communities surrounding the plant. After the release – which included quantities of MIC, hydrochloric acid and chloroform – the worker’s union printed hundreds of posters which they distributed throughout the community, warning:

..........• "Beware

of Fatal Accidents" Opposition legislators raised the issue in the State Assembly and the clamor surrounding these incidents culminated in a 1983 motion that urged the state government to force the company to relocate the plant to a less-populated area. Starting in 1982, a local journalist named Rajkumar Keswani had frantically tried to warn people of the dangers posed by the facility. In September of 1982, he wrote an article entitled "Please Save this City." Other articles, written later, bore grimly prophetic titles such as "Bhopal Sitting on Top of a Volcano" and "If You Do Not Understand This You Will Be Wiped Out." Just five months before the tragedy, he wrote his final article: "Bhopal on the Brink of a Disaster." In the midst of this clamour, in May 1982, Union Carbide sent a team of U.S. experts to inspect the Bhopal plant as part of its periodic safety audits. This report, which was forwarded to Union Carbide's management in the United States, speaks unequivocally of a "potential for the release of toxic materials" and a consequent "runaway reaction" due to "equipment failure, operating problems, or maintenance problems." In fact, the report goes on to state rather specifically: "Deficiencies in safety valve and instrument maintenance programs.... Filter cleaning operations are performed without slipblinding process. Leaking valves could create serious exposure during this process." In its report, the safety audit team noted a total of 61 hazards, 30 of them major and 11 in the dangerous phosgene/MIC units. It had warned of a “higher potential for a serious incident or more serious consequences if an accident should occur.” Though the report was available to senior U.S. officials of the company, nothing was done. (12) In fact, according to Carbide's internal documents, a major cost-cutting effort (including a reduction of 335 men) was undertaken in 1983, saving the company $1.25 million that year. Although MIC is a particularly reactive and deadly gas, the Union Carbide plant’s safety systems were allowed to fall into disrepair. Between 1983 and 1984, the safety manuals were re-written to permit switching off the refrigeration unit and shutting down the vent gas scrubber when the plant was not in operation. Cost-cutting measures directed by the Danbury Headquarters of Union Carbide included reducing the MIC plant crew from 12 to 6. In the control room, there was only 1 operator to monitor 70+ panels. Safety training was cut from 6 months to 15 days. On the night of the deadly MIC leak, none of the safety systems designed to prevent a leak - six in all - were operational, and the plant siren had been turned off. The process safety system included a design modification installed in May 1984 on the say-so of US engineers. This ‘jumper line’, a cheap solution to a maintenance problem, connected a relief valve header to a pressure vent header and enabled water from a routine washing operation to pass between the two, on through a pressure valve, and into MIC storage tank 610. Carbide’s initial investigation agreed that the pressure valve was leaking but declined to mention the jumper line. Exposure to this water led to an uncontrolled reaction; a deadly cloud of MIC, hydrogen cyanide, mono methyl amine soon settled over much of Bhopal, and people began to die. Yet when the Independent speaks of "rape", the Guardian of "disgrace" and Jon Snow of "a crime against humanity", they are not talking about THAT NIGHT - but of what has happened since to those who survived it. Today, 20 years after the disaster, Bhopal remains a humanitarian disaster. Their breathless bodies no longer able to push handcarts and lift heavy loads, thousands have fallen into destitution and their families have learned the lessons of the abyss, binding cloths round their middles to give an illusion of fullness, giving children unable to sleep from hunger water to fill their empty bellies. (13)

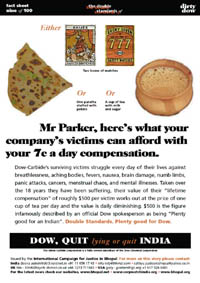

The factory, which killed so many, lies empty now and derelict, with the weather battering at it. Union Carbide left without cleaning it up. Tanks full of toxic chemicals have corroded and burst, dumping their contents onto the ground. Winds batter at loose metal sheets and gradually the buildings come apart. Worst of all, twenty monsoons (three months of heavy rain each year) have washed the toxins Carbide left behind deep into the soil, poisoning the drinking water of the same people Carbide gassed 20 years ago. According to former workers of the Union Carbide factory in Bhopal, while the factory was in operation, massive amounts of chemicals - including pesticides, solvents, catalysts and wastes - were routinely dumped in and around the factory grounds. These include deadly substances such as aldicarb, carbaryl, mercury, and several chlorinated chemicals and organic poisons. In 1977, Carbide constructed Solar Evaporation Ponds (SEPs) over 14 hectares 400 meters north of its factory. Toxic effluents and toxic wastes were routinely dumped there. Two tube wells dug in the vicinity of the SEPs were abandoned because of the noxious smell and taste of the water. A 1990 study by the Bhopal Group for Information and Action found di- and trichlorobenzenes in water samples taken from wells being used by communities living near the factory fence lines, and phthalates, chlorinated benzenes and aromatic hydrocarbons in the soil samples taken from the SEPs. In 1996, the State Research Laboratory conducted its own tests on water and concluded that the chemical contamination found is “due to chemicals used in the Union Carbide factory that have proven to be extremely harmful for health. Therefore the use of this water for drinking must be stopped immediately.” In 1999, Greenpeace and Bhopal community groups documented the presence of stockpiles of toxic pesticides (including Sevin and hexachlorocyclohexane) as well as hazardous wastes and contaminated material scattered throughout the factory site. The survey found substantial and, in some locations, severe contamination of land and water supplies with heavy metals and chlorinated chemicals. Samples of groundwater from wells around the site showed high levels of chlorinated chemicals including chloroform and carbon tetrachloride, indicative of long-term contamination. Over the years, the groundwater supplying an estimated 20,000 Bhopal residents has become heavily contaminated by Union Carbide’s toxic by-products. Lead, nickel, copper, chromium, hexachlorocyclohexane and chlorobenzenes were also found in soil samples. Mercury in some sediment samples was found to be between 20,000 and 6 million times the expected levels. According to a 2002 study by the Fact Finding Mission on Bhopal, many of Union Carbide’s most dangerous toxins can now be found in the breast milk of mothers living around the factory. Yet Dow Chemical, Union Carbide's new owner, has suggested that the polluted, not the polluter, should pay for any cleanup. (14) "Union Carbide lives on and waits for us to die." In March 1985, through the Bhopal Gas Leak Disaster (Processing of Claims) Act, the Indian Government arrogated to itself the sole powers to represent the victims in the civil litigation against Union Carbide. It then filed a $3 billion compensation suit on behalf of the victims in US federal court, but the case was sent to Indian courts in May 1986 on grounds of forum non-convenience, under the condition that Union Carbide would submit to the jurisdiction of Indian courts. Carbide’s lawyers devised a plan to delay all legal proceedings in order to squeeze the Indian government into accepting a low settlement. It contested the legitimacy of courts it had asked to be tried before. It pleaded to have ‘illiterate’ victims’ claims denied. It threatened to summon every individual survivor and appeal all Indian decisions in US courts. It denied it was a multinational. It claimed the gas was not ultra-hazardous. It blamed an unnamed saboteur. It appealed court orders for humanitarian relief, while professing its concern for the victims. Their first settlement offer was a paltry $100 million dollars, less than half the company’s liability insurance cover. By 1989, Carbide had spent at least $50 million on legal fees alone. How much they spent on PR companies such as Burson Marsteller, who they hired from Dec. 20 1984, has not been disclosed. It wasn’t until 1989 that a settlement was reached between

Carbide and the Indian Government – one made without the consultation

or consent of the survivors themselves. The victims were Many survivors found the settlement insulting. Indeed it was. It awarded them an average of 7 cents a day – the cost of a cup of tea – for a lifetime of unimaginable suffering. At Union Carbide, by contrast, “restructuring” - or asset stripping - in the immediate aftermath of Bhopal landed its managers and major shareholders huge windfalls in stock payments and golden parachutes. It paid only $200 million (or 43 cents a share) of its own money to settle the world’s largest peacetime massacre. In fact its annual report described 1989, the year of the settlement, as its ‘best financial year on record’. After having waited five long years for compensation, the Bhopal victims nevertheless filed suit to overturn the settlement in a case that went all the way to the Indian Supreme Court. Citing inaccurate statistics for the number of dead and injured victims, the court ruled in 1991 that the settlement amount would stand, simultaneously reinstating the criminal cases against Carbide, its CEO Warren Anderson, and other officials. Despite the settlement, two court cases remain pending: one civil, heard in the Southern District federal court in New York; the other criminal, heard before the Chief Judicial Magistrate’s court in Bhopal. The civil case - which is unrelated to the disaster itself - was filed in United States federal court in 1999 by Bhopal residents against Union Carbide. When it fled India after Bhopal, Carbide left tons of chemical wastes behind, and these have poisoned the groundwater and thousands of Bhopal residents. The civil case seeks a comprehensive cleanup of the contaminated site and the properties around the factory, and compensation and medical monitoring for those poisoned by Carbide’s chemical waste. The lawsuit, Bano v. Union Carbide, has survived four motions to dismiss, and has been reinstated twice by the 2nd Circuit Court of Appeals. The case is currently in the discovery process, and will soon proceed to trial. The criminal case - which is related to the 1984 Bhopal disaster – was originally filed in 1987, and reinstated in 1991. Both Warren Anderson, the former CEO of Union Carbide, and the Union Carbide Corporation itself face criminal charges in India of “culpable homicide” (or manslaughter). Both Anderson and Carbide have repeatedly ignored summons to appear in India for trial, and are officially considered “absconders” (fugitives from justice) by the Indian Government. While Anderson, if extradited and convicted, would face ten years in prison, Carbide faces a fine which has no upper limit.

From the start, the medical response ranged from inadequate to catastrophic. On THAT NIGHT, hospital officials frantically called Union Carbide, seeking a treatment protocol. When they finally got through, they were blithely assured that the gas which was killing thousands was “nothing more than a potent tear gas” and that victims merely had to “wash their eyes with water.” In a show of publicity as the bodies stacked up, Carbide flew a series of “top medical experts” to Bhopal to sing a chorus of reassurance. Dr. Hans Weil - reprimanded for unethical conduct by a US court for fudging medical data on behalf of the Johns-Manville corporation - predicted that ‘most victims would fully recover’. Pulmonary specialist Thomas Petty, also flown to Bhopal by Carbide, said that victims were ‘recovering rapidly’. No report made by Carbide-sponsored doctors was made available to the Indian government. Other ‘expertise’ included Carbide’s Dr. Bipin Awasia, who sent a telex to Bhopal recommending treatment with sodium thiosulphate. When in Bhopal, flanked by lawyers, he said he’d been mistaken. As a result, tens of thousands of ailing victims were denied a treatment that double blind clinical trials had shown to be effective. Success of the treatment would have proven that the gases had crossed into the bloodstream, thus generating more expensive damages against Carbide. The Indian Supreme court directed Carbide to build a 500 bed hospital from its own money. Instead, Carbide put £1000 into a trust in London and tried to transfer into this its shares in UCIL that had been seized by the Bhopal court due to Carbide’s non-appearance to face manslaughter charges. In 1994 it succeeded, thus evading the Bhopal court where the judge declared the transfer ‘malafide’. The 350 bed hospital took nearly ten years to build and within a year of opening was found to be profiteering with private patients, despite being bound to treat gas victims for eight years ‘in the first instance’.

To this day, the treatment of the Bhopal victims is impeded because

Dow-Carbide callously refuses to share all its medical information

on the toxic effects of the gases released that night, regarding

the information as a Today, the failure of the official system of health care contributes largely to the medical disaster in Bhopal. All research and monitoring of the long-term health effects of Union Carbide's gases were abandoned in 1994; they were only recently restarted in response to years of pressure from Bhopal survivors. So far no treatment protocols for symptom complexes associated with toxic exposure have been established and symptomatic treatment remains the mainstay of medical response. The indiscriminate prescription of steroids, antibiotics and psychotropic drugs is compounding the damage caused by the gas exposure.

In the prevailing situation of despair, the Sambhavna Trust believes in creating possibilities by generating compassion. At Sambhavna, survivors are offered free medical care through allopathy, ayurveda [an indigenous system of medicine based on herbs] and Yoga. The 21 staff members of the Sambhavna clinic [among whom 9 are survivors themselves] include five physicians, two yoga and two Panchakarma therapists and five community health workers who carry out health surveys, health education and community programs for better health.

The work carried out by the Sambhavna Trust since 1996 has shown that it is possible to evolve simple, safe, effective, ethical and participatory ways of treatment monitoring and research for the survivors of Bhopal. However, Sambhavna is small compared to the magnitude and complexity of the disaster. While an estimated 120,000-150,000 survivors of the disaster are today chronically ill, the clinic run by this trust has provided direct treatment to little over 16,000 people and provided support to about the same number through its health initiatives in 10 communities close to the Union Carbide factory. On April 27, 2005, a new building for the Sambhavna Clinic was inaugurated in Bhopal. Designed by the eminent Indian architects Shri Kishore Charavarti, Shri Yatin Choudhary, and Vishnu Chilotre, a civil engineer, the new clinic building incorporates many aspects of healing and environmental design. One of its most prominent features is a healing garden, in which organic herbs and ayurvedic medicines will be grown for use in the treatment of gas illnesses. For more information about Sambhavna and the new clinic, see www.bhopal.org.

In the wake of the disaster, the survivors assembled to fight for justice. In January 1985 a petition was circulated by Mr. Syed Irfan, leader of the Bhopal Gas Peedit Mahila Purush Sangarsh Morcha organization, and other survivors addressing the heads of the Madhya Pradesh government for medical and monetary aid. Few people were healthy enough after the disaster to do the sort of manual labor they had done beforehand. Many needed to be taught new crafts. The Indian Government initially set up lessons for survivors to learn trades, but did not provide decent jobs. The women at one stationary factory decided to unionize, forming the Bhopal Gas Peedit Mahila Stationary Karamchari Sangh or “Bhopal Gas-Affected Women’s Stationary Worker’s Union”. Led by future Goldman Award Winners Rashida Bee and Champa Devi Shukla, the union tried for months to negotiate with the government for decent wages. Finally, they marched from Bhopal to Delhi to petition the Prime Minister of India. It took them thirty-three days to reach Delhi, and even after having received some promises of support, little was done. Although the BGPMSKS struggle lasted for more than a decade, it was ultimately successful. Meanwhile, the union became deeply involved in the broader campaign for justice in Bhopal, becoming one of four key survivors organizations to spearhead the International Campaign for Justice in Bhopal. In one of their first acts in the newly-formed ICJB, survivors protested against Dow’s purchase of Union Carbide by traveling to Dow’s Indian Headquarters in Mumbai. There they popped balloons filled with red paint to illustrate that Dow now has Bhopal’s blood on their hands. In 2002 the women went on hunger strike in Bhopal in protest against

an attempt to water down the charges being pressed against the former

CEO of Union Carbide, Warren Anderson. Thousands of people worldwide

joined the fast in solidarity, including Diane Wilson of Texas,

who spent 30 days in the bed of a pickup truck, fasting in front

of Carbide’s Seadrift, Texas plant. Today, the International Campaign for Justice in Bhopal is stronger than ever before. Within the past two years the campaign has won several significant victories, improving the lives and the condition of the people of Bhopal. Despite the horror of THAT NIGHT and the chemical terror that its survivors have endured, the people of Bhopal continue their struggle for justice, for corporate accountability, and for their basic human right to an environment free of chemical poisons. The outcome of their struggle holds vast implications for all of us; if corporations aren't held accountable for their crimes, they're destined to be repeated. We all live in Bhopal. The only memorial ever built in Bhopal was privately funded, designed by the daughter of Holocaust victims. In bold letters, the inscription reads, “No Hiroshima, No Bhopal, We Want To Live.” With your help and that of others, the justice that has been so long delayed in Bhopal cannot be denied. Are you ready to Get Active? Find out how!! More information about Bhopal can be found in this Amnesty International report on the disaster, this comprehensive series of fact finding reports by the Fact Finding Mission on Bhopal, and this interview with Sathyu Sarangi of the International Campaign for Justice in Bhopal.

(1) The Washington Post. “India Seeks to Reduce Charge Facing Ex-Union Carbide Boss.” Rama Lakshmi, July 8, 2002. According to The International Medical Commission, Bhopal, “it is our opinion that, if properly defined, categories of permanent damage, partial or total disability, could include about 200,000 survivors.” International Perspectives in Public Health, 1996, Volumes 11 and 12, p. 27. (2) Amnesty International "Clouds of Injustice". 2004, p. 1. Available online at http://web.amnesty.org/pages/ec-bhopal-eng. See also The Hindu, available at http://www.hindu.com/thehindu/mp/2004/05/10/stories/2004051001720100.htm. (3) This figure is quoted both by VR Dhara (Dhara, VR; Dhara, Rosaline. “The Union Carbide Disaster in Bhopal: A Review of Health Effects.” Environmental Health Sept./Oct. 2002; Vol. 57, No. 5, pp. 391-404. Available here and Ward Morehouse (Morehouse W, Subramaniam MA. The Bhopal Tragedy: What Really Happened and What it Means for American Workers and Communities at Risk. New York: Council on International and Public Affairs, 1986), but alternate figures do exist. According to the Bhopal Methyl Isocyanate Incident Investigation Team Report, published by the Union Carbide Corporation (Connecticut, March 1985), plant inventory documents show that there were 41 metric tonnes of methyl isocyanate (MIC) in the tank that ruptured, #610. Union Carbide’s Team Report concludes that 24.5 metric tonnes of unreacted MIC escaped from tank 610 along with 11.79 tonnes of reaction products, and that 4.5 to 9.5 metric tonnes of solid reaction products were left behind in tank 610. The Report on Scientific Studies on the Factors Related to Bhopal Toxic Gas Leakage (Council for Scientific and Industrial Research, New Delhi, December 1985), a report produced by a team of Indian government scientists, similarly concludes that there were 42 metric tonnes of MIC in tank 610 at the time of the gas leak. However the report also concludes that only about 12 tonnes of MIC were used up to produce the 12.5 tonnes of solid residue estimated to be present. (4) These were: 1. flare tower (disconnected); 2. vent gas scrubber (out of caustic soda and inadequate for unsafe volume of gas); 3. water curtain (not functional; designed with inadequate height); 4. pressure valve; 5. run off tank (already contained MIC); 6. mandatory refrigeration for MIC unit (turned off to save money). See Dominique Lapierre and Javier Moro. Five Past Midnight in Bhopal. (Warner Books, 2002) (5) The Bhopal Gas Tragedy, 1984 - ? a report from the Sambhavna Trust, Bhopal, November 1998, pgs. 11-13. The Sambhavna Trust provides free clinic and community based medical care to Bhopal gas survivors: see www.bhopal.org. (6) The Bhopal Legacy, Greenpeace Research Laboratories, University of Exeter, November 1999, available at: http://www.bhopal.net/documentlibrary/bhopal.pdf. (7) See “Considerations in Taxable Corporate Acquisitions”, Thomas C Lacey, Jr., October 29th, 1998, p. 2. Available at: http://www.butlersnow.com/library_pdfs/1998_v1n5_pn.pdf. (8) Figure of 8,000 cited in New Scientist Magazine. “Fresh evidence on Bhopal disaster.” December 2, 2002. Available at: http://www.newscientist.com/news/news.jsp?id=ns99993140. Estimates come from independent relief organizations working in Bhopal immediately after the gas leak, and were based on evidence such as the number of funeral shrouds (kafans) sold by the local Cloth Merchant Association. See Five Past Midnight in Bhopal, Javier Moro & Dominique Lapierre, 2001, pgs. 365-366. (9) According to The Centre for Rehabilitation Studies’ (an office of the Madhya Pradesh government’s Bhopal Gas Tragedy Relief and Rehabilitation Dept.) 1998 Annual Report, the mortality rate among the exposed community in 1997 was 6.70/1000, whereas in the unexposed community it was 5.37/1000, producing a figure of 665 deaths above the mortality rate in the exposed community - or approximately 50 gas related deaths per month. No official figures exist for subsequent years. Further, according to a 1987 ICMR report, the mortality rate in the exposed community was 9.98/1000 and in the unexposed community was 6.03/1000, meaning approximately 150 gas related deaths per month in 1986. Assuming a steady ratio of depreciation in mortality of 6% per year, in 2003 there were therefore over 30 deaths per month due to gas exposure. However, it is worth noting that six monthly morbidity studies conducted by the ICMR between 1987-1991 show that the number of people with gas related symptoms actually increased in that period. (10) Exactly 521,262 according to the Indian Council for Medical Research (ICMR). See Five Past Midnight in Bhopal, Javier Moro & Dominique Lapierre, 2001, p 366. Figure of 500,000 cited in The New York Times. “Bhopal Seethes, Pained and Poor 18 Years Later.” Amy Waldman, September 21, 2002. (11) According to Union Carbide’s own documentation, obtained through discovery in the New York civil suit. Much of this documentation is available online, at http://www.bhopal.net/poisonpapers.html. See also New Scientist Magazine. “Fresh evidence on Bhopal disaster.” December 2, 2002. Available at: http://www.newscientist.com/news/news.jsp?id=ns99993140. And: The Financial Express. “Global Funds Tell Union Carbide To Settle Bhopal Gas Leak Claims.” Ajay Jain, December 5, 2002. Available at: http://www.financialexpress.com/fe_full_story.php?content_id=23259. (12) See The New York Times. “Union Carbide Had Been Told of Leak Danger.” Philip Shabecoff, January 25, 1985. See also The New York Times. “1982 Report Cited Safety Problems at Plant in India.” Thomas J. Lueck, December 11, 1984. Also: The Christian Science Monitor. “Confidential Indian report blames both US firm and subsidiary for Bhopal disaster.” Mary Anne Weaver, March 26, 1985. And: Time Magazine. “Clouds of Uncertainty; For Bhopal and Union Carbide, the tragedy continues.” Pico Iyer, December 24, 1984. (13) Nearly 80 percent of those exposed to the poison gases come from poor, working class families, of which nearly 50,000 people are today too sick to work and are thus driven to destitution. See The Bhopal Gas Tragedy, 1984 - ? a report from the Sambhavna Trust, Bhopal, November 1998, pgs. 11-13. The Sambhavna Trust provides free clinic and community based medical care to Bhopal gas survivors: see www.bhopal.org. (14) Dow has argued that since it does not own the former Union Carbide factory site in Bhopal (the site was only leased from the Madhya Pradesh government, and that lease has expired), it cannot be held responsible for the contamination there. This stand is contradicted by the Hazardous Waste (Management and Handling) Rule of 1989 594(E), Section 3 Sub section (1) and Section 4(1), which stipulates that the producers of the contaminated waste are responsible for decontamination. The “polluter pays” principle is also enshrined in the Environmental Protection Act, passed in India in 1986. Ruling in Vellore Citizens' Welfare Forum v. Union of India (1996) 5 SCC.647, the Indian Supreme Court declared that, “. . .Once the activity carried on is hazardous or inherently dangerous, the person carrying on such activity is liable to make good the loss caused to any other person by his activity irrespective of the fact whether he took reasonable care while carrying on his activity. The rule is premised upon the very nature of the activity carried on.” Elaborating on the “polluter pays” principle in MC Mehta v. Union of India (1997) 2 SCC 353, the Supreme Court ruled that “polluter pays” principle as interpreted by the Court means that “the absolute liability for harm to the environment extends not only to compensate the victims of pollution but also of restoring the environment degradation.” Nevertheless, Dow continues to argue that the Madhya Pradesh government is responsible for the cleanup (see the Daily Environment Report, No. 144, Monday, July 28, 2003). Additionally, an estimated $300 million of Union Carbide’s 1989 settlement remains undistributed to the victims. Although these funds exist solely to compensate the Bhopal victims for the loss of their health, their livelihoods, and their loved ones, Dow has suggested that the balance of these funds could be used to pay for a cleanup—turning the “polluter pays” principle entirely on its head. In summary, Dow has said both that local government should pay for the clean up AND that gas survivors should pay—the first is in contravention of lawful principle and common sense, while the second contradicts all notions of human decency. See The Midland Daily News. “Annual Meeting Draws Protests, Questions.” Beth Medley Bellor, May 10th, 2002. (15) Cited in The New York Times. “Bhopal Seethes, Pained and Poor 18 Years Later.” Amy Waldman, September 21, 2002. This refusal is inexplicable, as ‘trade secret’ provisions do not, in fact, apply. This was revealed in a Chemical Manufacturers Association (CMA) meeting shortly after the Bhopal disaster, at which Union Carbide representatives were present: “Trade secret protections under the federal standard extend only to chemical identity, not hazard information. …Chemical identity information which is a trade secret is made available to those who have a legitimate need for it, such as treating physicians.” See page 34 of the CMA Executive Committee Meeting Agenda, January 28, 1985, available at: http://www.chemicalindustryarchives.org/search/pdfs/cma/19850128_00000473.pdf.

|

The international student campaign to hold Dow

accountable for Bhopal, and its other toxic legacies around the world.

For more information about the campaign, or for problems regarding this

website, contact Ryan

Bodanyi, the Coordinator of Students for Bhopal.

WE

ALL LIVE  IN

BHOPAL

IN

BHOPAL

"The year 2003 was a special year in the history of the campaign for justice in Bhopal. It was the year when student and youth supporters from at least 30 campuses in the US and India took action against Dow Chemical or in support of the demands of the Bhopal survivors. As we enter the 20th year of the unfolding Bhopal disaster, we can, with your support, convey to Dow Chemical that the fight for justice in Bhopal is getting stronger and will continue till justice is done. We look forward to your continued support and good wishes, and hope that our joint struggle will pave the way for a just world free of the abuse of corporate power."

Signed/ Rasheeda Bi, Champa Devi Shukla

Bhopal Gas Affected Women Stationery Employees Union

International Campaign for Justice in Bhopal

This is what the www.studentsforbhopal.org site looked like in early 2008. For more recent information, please visit www.bhopal.net.

Key Facts

Key Facts Legal Issues

Legal Issues THAT NIGHT

THAT NIGHT Medical Issues

Medical Issues  Disaster By Design

Disaster By Design A Struggle for Justice

A Struggle for Justice The Second Tragedy

The Second Tragedy whom

22,000

whom

22,000  downward

to mix with smokes coming from somewhere nearer to the ground. A

dense fog formed. Nudged by the wind, it rolled across the road

and into the alleys on the other side. Here the houses were packed

close, ill-built, with badly-fitting doors and windows. Those within

were roused in darkness to the sound of screams with the gases already

in their eyes, noses and throats. It burned terribly, it felt like

fire.

downward

to mix with smokes coming from somewhere nearer to the ground. A

dense fog formed. Nudged by the wind, it rolled across the road

and into the alleys on the other side. Here the houses were packed

close, ill-built, with badly-fitting doors and windows. Those within

were roused in darkness to the sound of screams with the gases already

in their eyes, noses and throats. It burned terribly, it felt like

fire.

“trade

secret”.

“trade

secret”.